- Declaration of quality policyEnvironmental policyOccupational safetyEnvironmental policyInternational certificationDRC Conflict-Free declarationGreen product certification of ACESSupply Chain Management

-

Declaration of quality policy

I. The idea of getting the right quality the very first time is very simple and straightforward: do things right the first time! We believe that quality is conforming to requirements.

The price of requirements compliance is the cost of doing things right the first time while the price of non-conformities is the wastage of resource. We believe that quality should be managed by prevention rather than inspection and error correction. Prevention requires thinking, planning, and analyzing to anticipate where errors may occur and taking the steps to prevent them from happening. Problems are usually caused by a lack of or error in product or service requirements. The prevention process includes: determining the requirements of the product or service, product development and process control, and taking the steps to get results. This is an everlasting process of improvement. The ultimate goal of quality improvement is zero-defect products and services, i.e. quality as a habit. “Zero defects” is not just a slogan for motivating morale, instead, it is a work attitude and commitment to prevention. Everyone in the organization shall get involved in quality improvements and be determined to meet the requirements right the first time, every time, and accept nothing but requirements compliance.

II. With the full support of the management and efforts of the entire work forces, ACES is committed to continuous improvement in bettering the process and quality to drive ACES into becoming a global leader in connector manufacturing. Enhance company image, organizational effectiveness, personnel growth, project management, product quality and the like through continuous improvement and the concept of total quality management which has been transformed into its corporate culture. ACES will grow and thrive in this high-quality corporate culture environment.

III. We have been pursuing excellence all the time. Embracing the corporate culture of "knowledge, vision, value, attitude, commitment and execution" we are enhancing the quality responsibility awareness of each employee to make better the product quality and reliability. Excellent quality is our shared responsibility. Based on the quality vision of "Doing things right the very first time for continuous improvements and pursing excellent quality," ACES is committed to assume social, enterprise and employee responsibility with continuous improvements and bettering products and services. -

Environmental policy

Compliant with regulations

Compliant with regulations Energy saving

Energy saving Resources re-use

Resources re-use Better environment

Better environment -

Occupational safety

People

orientedPrevention

orientedContinuous

improvementTotal

participationLaw

abidance -

Environmental policy

Focusing on connectors and wires and cable compounds for various types of electronics, computers and communication products, ACES is committed to "coexistence with nature and is people-oriented" and "protecting the earth and employees' health." The environmental/safety impact is fully considered in the production and operating process. Based on prevention and continuous improvements, we pursue the following environmental safety policy:

1. Adopt new technology - use environmentally friendly materials and new production processes to reduce the environmental impact and hazard risks generated by the production process.

2. Implement hazard prevention - regularly identify environmental factors and major hazards, develop management plans and supervise execution of the latter.

3. Comply with regulations - comply with national, local and industry relevant regulations as a law-abiding enterprise.

4. Strive to recycle resources - save energy, execute wastes classification and recycling.

5. Commitment to continuous improvement - continuous improvement over environmental pollution and health hazards, improve environmental / health and safety performance.

6. Implement environmental safety training - implement environmental safety education and safety management, improve environmental protection / health and safety awareness. -

International certification

Certification Name System First Acquisition Date Latest Acquisition Date Latest Effective Date ISO 9001 Quality Management System 2004/3/19 2024/1/30 2027/1/29 IATF 16949 Automotive Quality Management System 2015/3/4 2024/1/30 2027/1/29 IECQ QC080000 Hazardous Substance Process Management System 2014/5/16 2023/4/13 2026/5/15 ISO 13485 Medical Devices - Quality Management Systems 2023/6/26 2023/6/26 2026/6/26 ISO 17025 Laboratory Management System 2022/1/7 2022/1/7 2025/1/6 ISO 14001 Environmental Management System 2016/1/13 2024/12/26 2028/1/12 ISO 45001 (ANAB) Occupational Health and Safety Management System 2016/1/13 2023/2/11 2026/2/10 ISO 14064-1 Greenhouse Gas Emission Inventory Verification Statement 2022/4/28 2024/7/31 N/A RBA VAP RBA VAP 2019/01/02 2024/04/16 2026/04/16 ISO 27001 The maintenance and management of computer server rooms, backbone network services, and related support systems. 2024/12/31 2024/12/31 2027/12/30 Certification Name System First Acquisition Date Latest Acquisition Date Latest Effective Date ISO 9001 Quality Management System 2004/3/19 2024/1/30 2027/1/29 IATF 16949 Automotive Quality Management System 2015/3/4 2024/1/30 2027/1/29 IECQ QC080000 Hazardous Substance Process Management System 2014/5/16 2023/4/13 2026/5/15 ISO 13485 Medical Devices - Quality Management Systems 2023/6/26 2023/6/26 2026/6/26 ISO 17025 Laboratory Management System 2022/1/7 2022/1/7 2025/1/6 ISO 14001 Environmental Management System 2016/1/13 2024/12/26 2028/1/12 ISO 45001 (ANAB) Occupational Health and Safety Management System 2016/1/13 2023/2/11 2026/2/10 ISO 14064-1 Greenhouse Gas Emission Inventory Verification Statement 2022/4/28 2024/7/31 N/A RBA VAP RBA VAP 2019/01/02 2024/04/16 2026/04/16 ISO 27001 The maintenance and management of computer server rooms, backbone network services, and related support systems. 2024/12/31 2024/12/31 2027/12/30 Certification Name System First Acquisition Date Latest Acquisition Date Latest Effective Date ISO 9001 Quality Management System 2004/3/19 2024/1/30 2027/1/29 IATF 16949 Automotive Quality Management System 2015/3/4 2024/1/30 2027/1/29 IECQ QC080000 Hazardous Substance Process Management System 2014/5/16 2023/4/13 2026/5/15 ISO 13485 Medical Devices - Quality Management Systems 2023/6/26 2023/6/26 2026/6/26 ISO 17025 Laboratory Management System 2022/1/7 2022/1/7 2025/1/6 ISO 14001 Environmental Management System 2016/1/13 2024/12/26 2028/1/12 ISO 45001 (ANAB) Occupational Health and Safety Management System 2016/1/13 2023/2/11 2026/2/10 ISO 14064-1 Greenhouse Gas Emission Inventory Verification Statement 2022/4/28 2024/7/31 N/A RBA VAP RBA VAP 2019/01/02 2024/04/16 2026/04/16 ISO 27001 The maintenance and management of computer server rooms, backbone network services, and related support systems. 2024/12/31 2024/12/31 2027/12/30 Certification Name System First Acquisition Date Latest Acquisition Date Latest Effective Date ISO 9001 Quality Management System 2004/3/19 2024/1/30 2027/1/29 IATF 16949 Automotive Quality Management System 2015/3/4 2024/1/30 2027/1/29 IECQ QC080000 Hazardous Substance Process Management System 2014/5/16 2023/4/13 2026/5/15 ISO 13485 Medical Devices - Quality Management Systems 2023/6/26 2023/6/26 2026/6/26 ISO 17025 Laboratory Management System 2022/1/7 2022/1/7 2025/1/6 ISO 14001 Environmental Management System 2016/1/13 2024/12/26 2028/1/12 ISO 45001 (ANAB) Occupational Health and Safety Management System 2016/1/13 2023/2/11 2026/2/10 ISO 14064-1 Greenhouse Gas Emission Inventory Verification Statement 2022/4/28 2024/7/31 N/A RBA VAP RBA VAP 2019/01/02 2024/04/16 2026/04/16 ISO 27001 The maintenance and management of computer server rooms, backbone network services, and related support systems. 2024/12/31 2024/12/31 2027/12/30 -

DRC Conflict-Free declaration

ACES hereby declares that all products offered to customers are DRC Conflict-Free:

ACES is or shall be committed to investigating the supply chain to ensure that metals such as Au, Ta, Tungsten, Co, and Sn are not provided by anarchy or gangsters mined in or smuggled from the conflict zone of the Democratic Republic of the Congo . Metals exported by the following countries are not DRC Conflict-Free compliant: Democratic Republic of the Congo (DRC), Rwanda, Uganda, Burundi, Tanzania, Kenya (the United Nations Security Council has determined that metals mined by these countries are derived from Congolese veins).

ACES warrants that metals employed by products sold to its customers are DRC Conflict-Free compliant.

Company Name: ACES Co., Ltd. (ACES)

Company representative: Yuan Wanding

Company representative title: chairman

Date: 10/22/2015 -

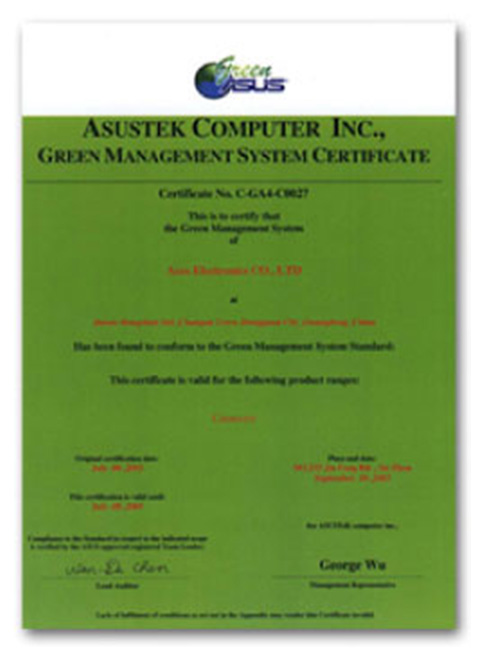

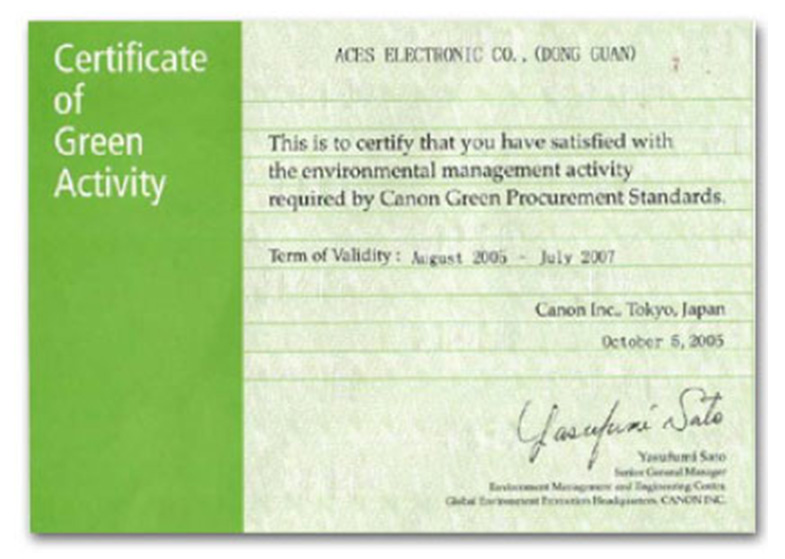

Green product certification of ACES

ASUS certificate

ASUS certificate Certificated from CANON

Certificated from CANON -

Supply Chain Management

ACES has a large number of suppliers. It selects qualified suppliers and requires them to fulfill their social responsibilities in environmental protection, safety or health issues according to its "Supplier Assessment and Control Guidelines."

The first on-site suppliers assessment:

Once the "Supplier Evaluation Application Form" gets approved by the units-in-charge, set up an assessment team with members from the relevant units to field assess the suppliers in terms of manufacturing capabilities, quality management capabilities, RoHS compliance and CSR conformity level according to the "Supplier Evaluation Form."

Qualified suppliers are required to provide information:

(1) Regarding qualified suppliers: relevant units shall have them provide business license and bank account information and sign off and hand over the following documents: "Purchase Contract," "Integrity Letter of Commitment," "RoHS contract guarantee," "Confidentiality Agreement," "ACES Quality Agreement" and "Supplier SRC statement."

(2) Suppliers are required to be ISO9001 certified or to submit the verification plan or get ISO9001 certification under the supervision of the procurement unit.

Regular evaluation over qualified suppliers:

In two stages of annual assessment and quarterly review:

(1) Supplier annual assessment

Procurement officers shall organize an assessment team according to the "Annual supplier audit plan" to field assess RoHS compliance of qualified suppliers' manufacturing capabilities and quality management capabilities and products according to the "Supplier Evaluation Form".

(2) Supplier quarterly assessment

Regarding suppliers with transactions and have gone through incoming inspection: assess quarterly.

Supplier de-listing:

Regarding suppliers with severe regulation violations, e.g. against RoHS directive, against labor or ethics relevant laws, major quality defects, graded D in two consecutive quarterly assessments, or graded D by field assessments: procurement officers may file in writing for their de-listing to the local GM for approval. Manufacturers who failed to meet the criteria shall get de-listed and replaced by a new one.